Laser Brazed Roof

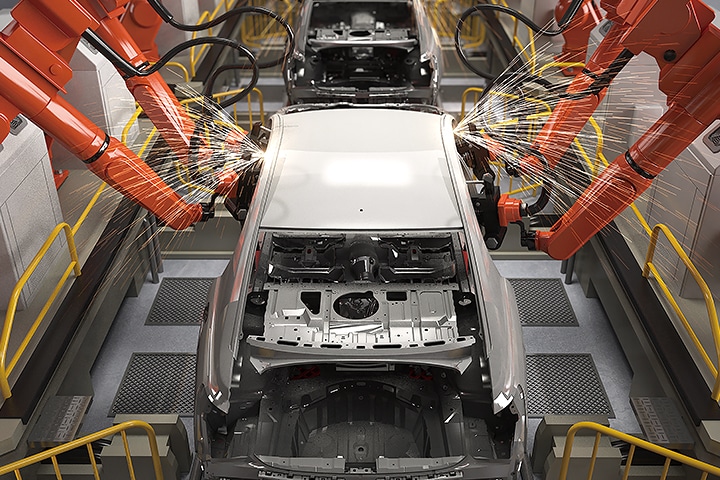

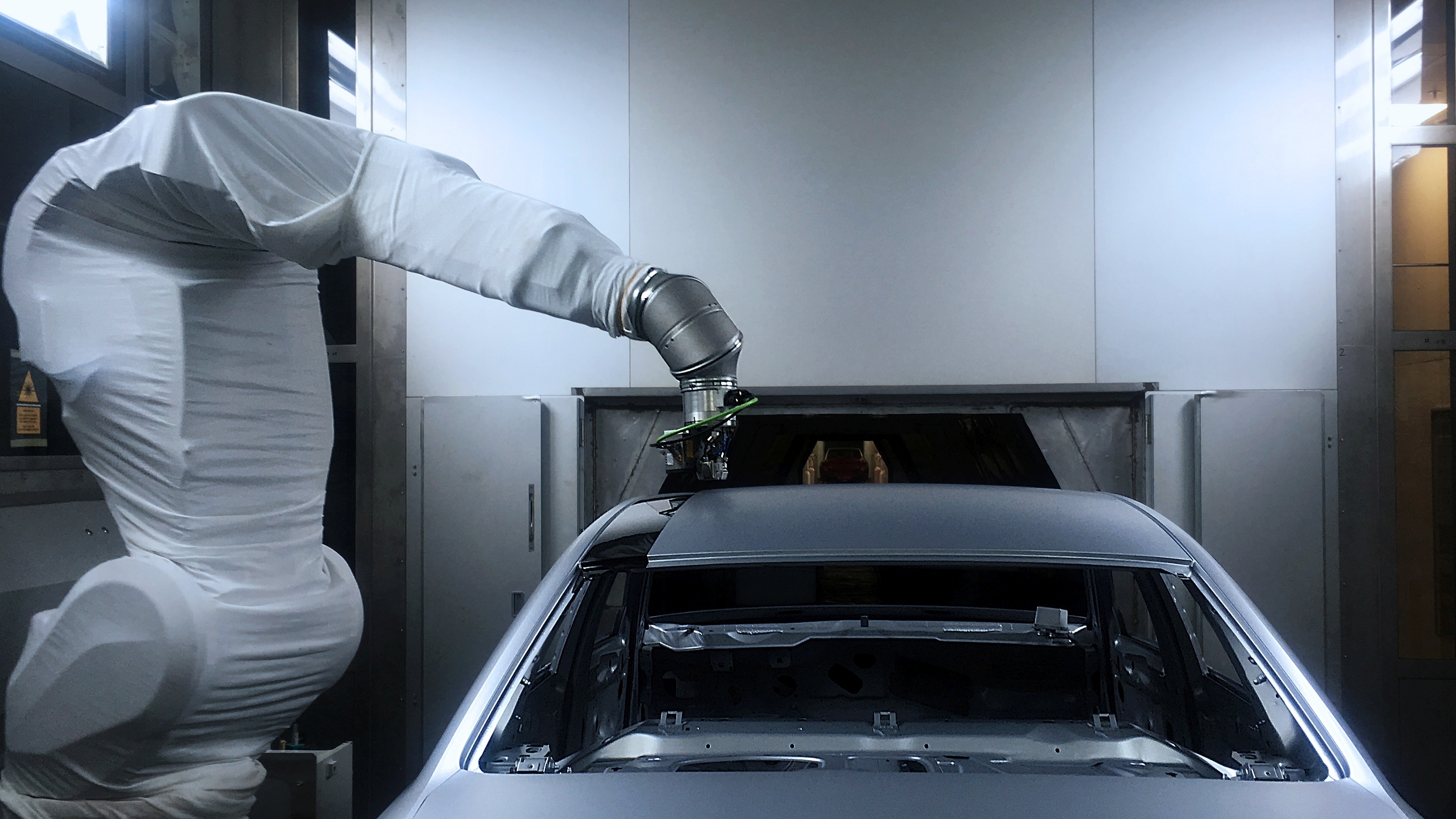

A big change to take note of is the outer roof replacement procedure.

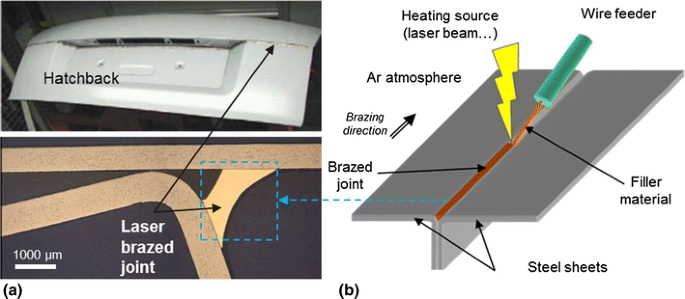

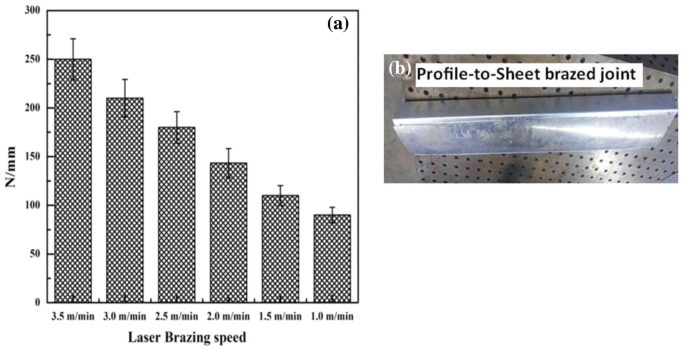

Laser brazed roof. Brazing is a joining process whereby a filler metal or alloy is heated to melting temperatures above 450 c and distributed between two or more close fitting parts without actually melting the base material. Thanks to these advantages laser brazing is employed for visible joints in areas such as tailgates roof joints and c columns. From the factory the accords roof is attached with weld bonding in the corners and laser brazing on the sides. It s a new process for acura that allows the roof to be seamlessly joined with the side panels.

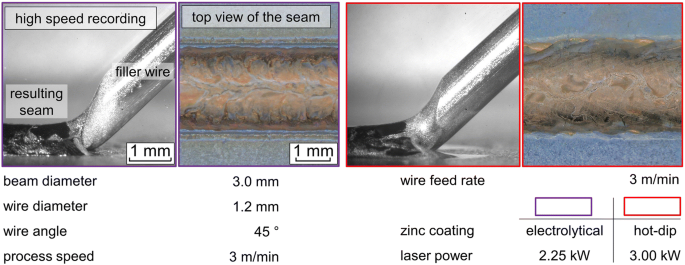

Implementing laser brazing for the ditch joint attaching the roof and the side panel of the car. Learn everything you need to know about roof repair in special laser brazed roofs applying oem approved repair methods. These panels are typically zinc coated for improved corrosion protection and the brazed joints are visible to consumers. Brazing s main advantages compared to welding are the smooth surfaces that are produced and the ability to avoid melting the zinc coating which avoids corrosion or further treatment that would be necessary otherwise.

One new development acura is especially proud of is the tlx s new laser brazed roof. Laser brazing is a widely used process for joining closure panels in automotive manufacturing exemplified by joints such as the upper to lower panels of a liftgate or the roof to body side outer panels. Compared to laser beam or spot welding brazing welding improves the aesthetics of the joint so clearly that a roof seam no longer has to be covered by a plastic strip. This procedure differs a lot from any honda roof replacement procedure we have seen in the past.

Compared to laser welding or spot welding laser brazing improves the aesthetics of the joint so dramatically that the ditch molding can be omitted. Laser brazing high mechanical stability minimal heat affected zones and smooth surfaces.